Maximizing Efficiency with Advanced Features of Soldering Stations:

Soldering stations are essential tools in electronics manufacturing, repair, and hobbyist workshops. They provide precise control over temperature, ensuring proper soldering of components onto circuit boards. While basic soldering stations serve their purpose, advanced models offer additional features that can significantly enhance efficiency and productivity. In this article, we’ll explore the advanced features of soldering stations and how they can help maximize efficiency in various soldering applications.

Temperature Control and Stability:

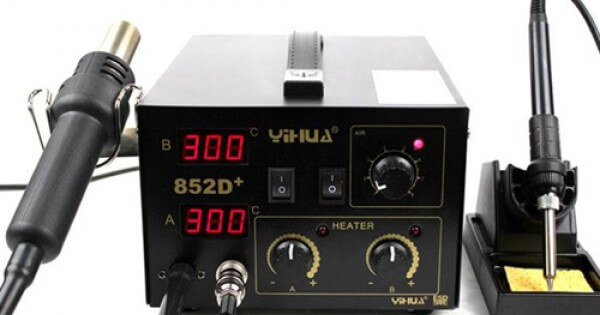

Temperature control is critical in soldering to ensure proper melting and flow of solder without damaging sensitive components. Advanced soldering stations feature precise temperature control mechanisms that allow users to set and maintain the desired temperature with accuracy. Digital displays provide real-time feedback, allowing users to monitor temperature changes and adjust settings as needed. Additionally, advanced soldering stations often incorporate temperature stability features that minimize fluctuations, ensuring consistent performance and high-quality solder joints.

Adjustable Power and Heating Profiles:

Another advanced feature of soldering stations is the ability to adjust power levels and heating profiles to suit specific soldering tasks. Different soldering applications may require varying levels of power and heat, depending on factors such as the size of the components, the type of solder used, and the complexity of the circuit board. Advanced soldering stations allow users to customize power settings and heating profiles, optimizing performance for each application. By fine-tuning power levels and heating profiles, users can achieve optimal soldering results with greater efficiency and precision.

Fast Heat-Up and Recovery Times:

Advanced soldering stations are equipped with high-performance heating elements and efficient thermal management systems that enable fast heat-up and recovery times. Quick heat-up times mean users can start soldering sooner, reducing waiting times and improving workflow efficiency. Similarly, fast recovery times ensure that the soldering iron maintains the desired temperature even during prolonged soldering sessions or when soldering large components. By minimizing downtime and interruptions, fast heat-up and recovery times help maximize productivity and throughput in soldering operations.

Digital Controls and Programmable Settings:

Many advanced soldering stations feature digital controls and programmable settings that offer enhanced functionality and convenience. Digital displays provide clear and intuitive interfaces for adjusting temperature, power, and other parameters, allowing users to make precise adjustments with ease. Additionally, programmable settings enable users to save and recall custom temperature profiles for different soldering tasks or materials. By eliminating the need for manual adjustments and repetitive setup, digital controls and programmable settings streamline soldering processes and reduce the risk of errors.

Integration with Soldering Accessories:

Advanced soldering stations often integrate seamlessly with a variety of soldering accessories and peripherals, further enhancing their versatility and efficiency. These accessories may include soldering irons with interchangeable tips, soldering tweezers for precision soldering of small components, and soldering fume extractors for improved safety and air quality. By incorporating compatible accessories into their soldering setups, users can tackle a wider range of soldering tasks with greater ease and efficiency, reducing the need for additional equipment and simplifying workflow management.

Safety Features and Monitoring Systems:

Safety is paramount in soldering operations, especially when working with high temperatures and potentially hazardous materials. Advanced soldering stations are equipped with a range of safety features and monitoring systems designed to protect users and equipment from accidents and damage. These features may include overheat protection mechanisms, automatic shut-off functions, and built-in safety alarms. Additionally, some soldering stations feature integrated monitoring systems that continuously monitor temperature, power, and other parameters, providing real-time feedback and alerts to users in the event of abnormal conditions.

Final Thoughts:

In conclusion, advanced features of soldering stations offer a range of benefits that can help maximize efficiency and productivity in soldering operations. From precise temperature control and adjustable power settings to fast heat-up and recovery times, digital controls and programmable settings, integration with soldering accessories, and safety features and monitoring systems, advanced soldering stations empower users to tackle a wide range of soldering tasks with confidence and precision. By investing in advanced soldering stations with these features, electronics manufacturers, repair technicians, and hobbyists can achieve optimal soldering results while minimizing downtime, errors, and risks.