Strategize: Understanding Electric Vehicle Components for Cost Efficiency

As the global electric vehicle (EV) market is projected to reach a staggering $800 billion by 2027, it becomes imperative to delve into the components that make up these innovative vehicles. The efficiency and cost-effectiveness of electric vehicle components play a crucial role in determining not only their performance but also their affordability for consumers.

The Core Elements of Electric Vehicle Components

Electric vehicle components primarily include batteries, electric motors, power electronics, and charging systems. Each component possesses unique attributes that contribute to the overall functionality of EVs. For instance, lithium-ion batteries are favored for their high energy density and longevity; however, they come with significant costs associated with raw materials like cobalt and nickel. Additionally, advancements in power electronics have improved energy conversion efficiency but can add complexity—and thus cost—to manufacturing processes.

Largest Battery Manufacturers: A Cost Perspective on Electric Vehicle Components

The largest battery manufacturers dominate the landscape by driving down costs through economies of scale while simultaneously investing heavily in research and development. Companies such as CATL and LG Chem have streamlined production techniques which allow them to reduce per-unit costs significantly. Furthermore, strategic partnerships with automotive companies enable bulk purchasing agreements that further lower expenses related to sourcing essential materials needed for battery production.

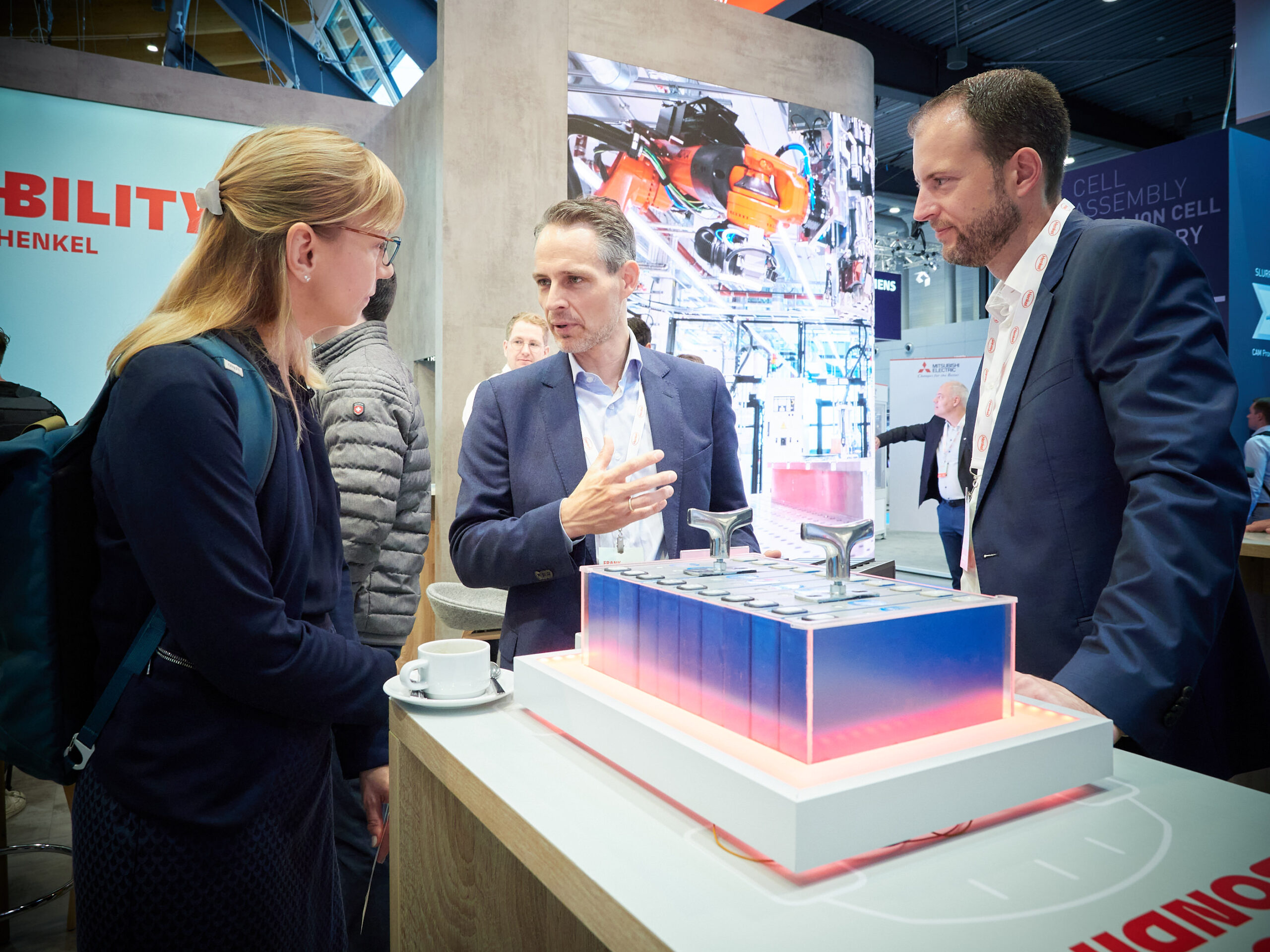

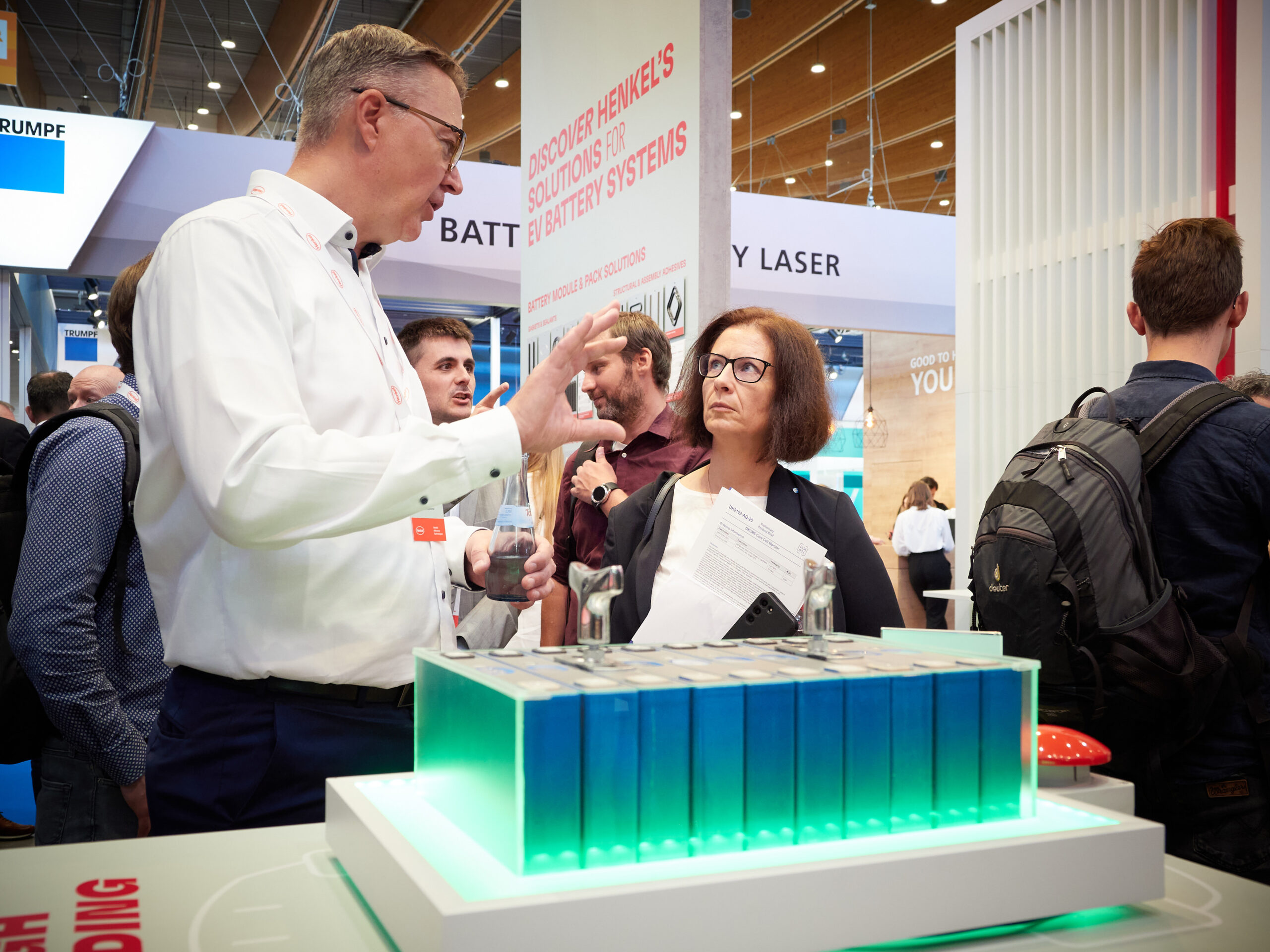

The Battery Show: Key Features Impacting Costs

- Innovation Showcase: The Battery Show highlights cutting-edge technologies aimed at reducing manufacturing costs across various battery types.

- Sourcing Solutions: Attendees gain insights into sustainable sourcing practices that can mitigate price volatility associated with critical minerals.

- Networking Opportunities: Collaborations formed during this event often lead to joint ventures focused on cost reduction strategies within supply chains.

- User-Centric Design: Discussions around user needs help manufacturers create more efficient products without inflating prices unnecessarily.

- Sustainability Focus: Emphasis on recycling initiatives contributes positively towards lowering long-term operational costs associated with waste management in EV production.

A Conclusive Overview on Cost Aspects of Electric Vehicle Components

The exploration of electric vehicle components reveals a complex interplay between innovation and cost-efficiency. While initial investments may be substantial due to advanced technology requirements—particularly concerning batteries—the potential savings from reduced fuel consumption and maintenance over time cannot be overlooked. Ultimately, understanding these dynamics allows stakeholders within the industry to strategize effectively toward achieving both profitability and sustainability in an increasingly competitive market environment.

Click The Battery Show.