A Comprehensive Buyer’s Guide to Selecting Low Voltage Power Cables

When it comes to selecting the right low-voltage power cables, it is essential to understand their functionality, features, and applications. In this buyer’s guide, we will provide the necessary information to make an informed decision. From understanding technical specifications to evaluating performance factors, this guide is designed to help you navigate the world of lv power cables. So, let’s dive right in!

1. Know the Basics: Before delving into the selection process, it’s important to have a basic understanding of LV power cables. These cables are commonly used for transmitting electrical energy below 1,000 volts. They serve various applications, such as residential, commercial, and industrial sectors.

2. Consider Cable Types: Low-voltage power cables come in different types, each suited for specific purposes. Some common types include:

a. PVC (Polyvinyl Chloride) Cables: These cables are cost-effective, flame-retardant, and widely used for indoor installations.

b. XLPE (Cross-linked Polyethylene) Cables: They offer excellent resistance to high temperatures and have good insulation properties, making them suitable for outdoor and industrial applications.

c. Rubber Cables: Known for their flexibility and durability, rubber cables are often used in harsh environments or for temporary installations.

3. Understand Cable Design: It is crucial to understand the cable design features that will affect performance and determine the suitability for your project. Key design considerations include:

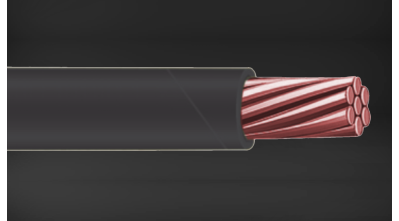

a) Conductor Material: Copper and Aluminum are the most common materials used for low-voltage power cable conductors. Copper offers better electrical conductivity, while Aluminum is more cost-effective.

b) Insulation Material: Different insulation materials have varying temperature ratings, electrical properties, and resistance to external factors such as chemicals or moisture.

c) Shielding: For applications that require protection against electromagnetic interference (EMI), shielded cables may be necessary.

4. Assess Technical Specifications: To ensure the LV cable meets your specific requirements, you need to consider various technical specifications:

a) Voltage Rating: Check that the cable’s voltage rating matches your electrical system requirements.

b) Current Capacity: Determine the cable’s ability to carry the required electrical current safely.

c) Temperature Rating: Confirm that the cable can withstand the intended operating temperature without degradation.

d) Bend Radius: Consider the minimum bend radius required for installation to prevent damage to the cable.

5. Evaluate Quality Standards and Certifications:

Look for lv power cables that comply with recognized quality standards, such as the International Electrotechnical Commission (IEC) or the American National Standards Institute (ANSI). These standards ensure the cables meet specific safety, performance, and quality criteria.

6. Consider Environmental Factors: Determine the environmental conditions that your cables will be exposed to:

a) Outdoor or Indoor: For outdoor or underground installation, cables must be suitable for direct burial, UV resistance, and have proper moisture protection.

b) Chemical or Oil Resistance: In chemically or oil-laden environments, cables with appropriate resistance properties are essential to prevent damage.

c) Flame Retardancy: For applications where fire safety is paramount, choose cables with enhanced flame retardant properties.

7. Cost vs. Quality: While cost is an important consideration, it should not be the sole determining factor. Striking a balance between quality and affordability is crucial. Investing in high-quality power cables may save you money in the long run by reducing maintenance and ensuring reliable performance.

Selecting the right lv power cable ensures a safe and efficient electrical installation. By considering the cable types, design features, technical specifications, quality standards, environmental factors, and cost, you can confidently make an informed decision.